Electronic and Fine Mechanics Tools by ELORA: functionality, accuracy and safety

– functionality, accuracy and safety

Precision mechanics, electronics and electrical engineering: Tools for working safely on electro static sensitive components

ESD stands for Electro Static Discharge. This refers to a short and high electrical discharge caused by a large potential difference. The reason for this potential difference is an electrical charge of the person in combination with an electrically insulated component. Often such a charge is caused by frictional electricity which is not perceived by the person concerned.

Even the smallest amounts of electric charges can cause lasting damage to electronic components. A complex set of measures helps to counteract this danger.

The establishment of an EPA (Electrostatic Protected Area) workstation, for example, is always aimed at the controlled discharge of the electrostatic charge to ground potential.

Sensitive components and assemblies remain fully functional

Discharging work clothing, the typical ESD wrist strap with coiled cable and electrostatically safe tools are fixed components of such a workplace. These tools are marked accordingly.

ESD tools from ELORA comply with the ESD standard DIN-IEC 61340-5-1. They are manufactured with handles made of special discharging material with a surface resistance in the range of 106 to 109 ohm.

The handle provides the necessary contact surfaces to the user’s hand to ensure a defined discharge process – sensitive components and assemblies remain fully functional despite human mechanical impact.

ELORA ESD special pliers – Well designed down to the smallest detail

The extensive ELORA ESD pliers range meets the requirements of professional users. The antistatic, ergonomic and anti-slip two-component handles enable safe guidance of the pliers and optimum force transmission. ELORA-ESD pliers are available with a wide variety of heads or jaws.

Production specification of our ESD pliers

The pliers blanks are hot forged in our own high-precision special dies with narrow tolerance ranges. The result is a material quality that is superior to stamped or cold-formed blanks due to its molecular structure.

The individual material selection is based on the different requirements of gripping and cutting pliers. Gripping pliers are subject to torsional and bending forces as well as greater stress on surfaces and edges. By using carbon steel, we achieve the optimum hardness value of 45 HRC.

Perfect shape perfection and uncompromising cutting edge sharpness

Cutting pliers are subjected to operating torque and bending forces, especially in the area of the cutting edges. In order to ensure a sufficient cutting edge hardness with high flexibility and load-bearing capacity, we use carbon steel C 60 or high-alloy chrome vanadium steels, depending on the model. The maximum cutting edge hardness is 65 HRC.

For the sovereign processing of extremely hard or tough materials, we equip part of our side and diagonal cutter range with cutting edges made of carbide. These are ideal for precisely cutting through piano, nickel or diode wire, as well as glass fibers, which are increasingly used in the electronics and aerospace industries.

We achieve perfect form and uncompromising edge sharpness in the traditional hand-grinding process – an impressive finish through the final surface treatment or refinement. Piece by piece.

ESD tools by ELORA: side cutters, pliers, screwdrivers and tweezers for high-precision work

Our ESD tools are manufactured in Germany and meet the highest quality standards. The robust construction guarantees a long service life with the highest precision – as you are used to from ELORA!

ESD Set

600-S15

- 15 pcs.

- in black plastic box with 2-colour foam material

- TORX®=reg. trade mark of Acument Intellectual Properties, LLC. USA

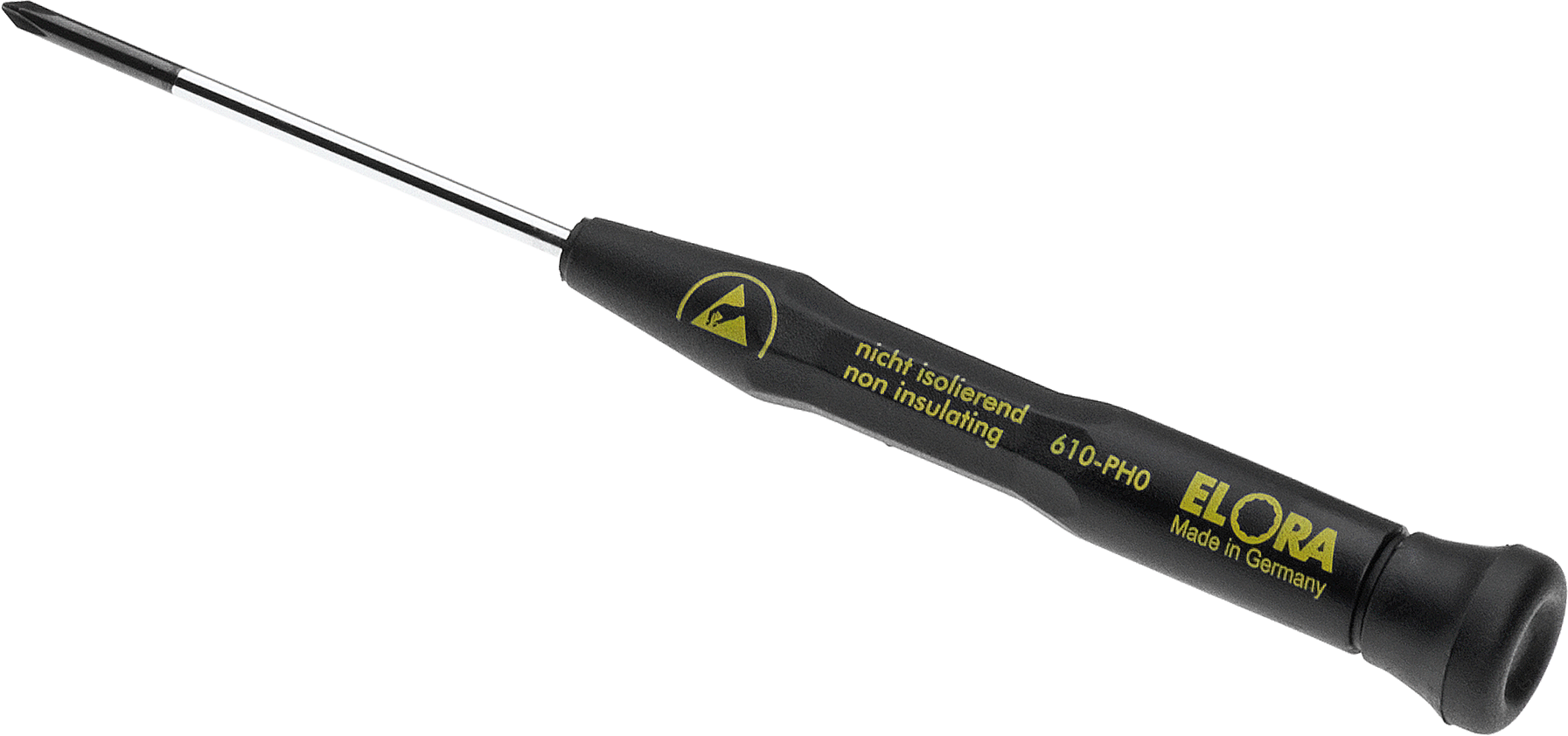

Electronic Screwdriver ESD

610-PH…ESD

- ffor cross slotted screws

- for work with electrostatic endangered components

- blade through hardened and chrome-plated, tip gunmetal-finish

- ESD precision handle with rotating cap, surface resistance 106–109 Ohm

Electronic Oblique Cutter ESD

4580

- for frontal virtually flush cutting of wires, can be used horizontally and vertically for work with electrostatic endangered components

Electronic Snipe Nose Plier ESD

4690

- angled, straight long jaws, half round tips, box joint, with double opening leaf spring, polished and high gloss gunmetal-finish, with 2-C ESD handles, surface resistance 106–109 Ohm

- serrated gripping surface

Electronic Round Nose Plier ESD

4720

- short jaws, round tips, box joint, with double opening leaf spring, polished and high gloss gunmetal-finish, with 2-C ESD handles, surface resistance 106–109 Ohm

- smooth gripping surface

Electronic Side Cutter ESD

4760

- pointed head, maximum stability under load by additional inductive hardening and box joint, with double opening leaf spring, polished and high gloss gunmetal-finish, with 2-C ESD handles, surface resistance 106-109

- cutting edge hardness 61-63 HRC

Electronic Tweezer

5260-ST

- for all fine gripping and assembly work

- anti-glare satin finish, grooved gripping surfaces

- stainless, antimagnetic, acid-proof

- ELORA-Special-Chrome-Nickel-steel

ELORA on Social Media

Follow us on Facebook & Instagram for more!

Contact

Questions? We will be happy to help you!

We are looking forward to your message.